Super capacitor lithium battery pack / 3.6V high powered Lithium Primary Battery Gas Meter NB-IoT Meter and Sensor

WR14505 Li-SO2 Battery Long Life High Continuous / Pulse Current

| Nominal Capacity | 8500mAh | Nominal Voltage | 3.6V |

| Maximum Continuous Current | 0.5A | Maximum Pulse Discharge Current | 2.0A |

| Temperature | ≤ 30℃ | Humidity | ≤ 75%RH |

| Operating Temperature | -55℃ to +85℃ | Max Weight | 53g |

| Self-discharge Rate | 2% | Shelf Life | 10 years |

1. Battery Characteristic

- High Voltage

Single battery nominal voltage up to 3.6V, the working voltage varies with the load, generally between 3.3V ~ 3.6V

- High Energy Density

We provide the specific energy density up to 241Wh/kg

- Wide Operating Temperature Range

The battery can be in work between -55℃~ +85℃

- Stable Operating Voltage

Stable operating voltage, more than 90% of the capacity could be output with a fixed voltage

- Long Shelf Life

The battery self-discharge less than 2% per year at room temperature

Battery sealing using the fully sealed structure to reduce the leakage of the battery, make the battery can be stored at room temperature for more than 10 years

- UPC(Ultra Pulse Capacitor)

An auxiliary battery capacitor designed for large pulse current.

The combination of UPC and lithium SOCl2 bobbin battery is more safety, and the combination can provide large discharge current. It’s a good choice to replace spiral battery.

2. The working principle of UPC

Lithium SOCl2bobbin battery and UPC in parallel, high load of pulse completed by the Ultra Pulse Capacitor, not affected by the passivation.High load pulse bycompleted UPC, ahead of the next pulse lithium battery recharge UPC, after a full charge the discharge capacity ofUPC is constant, so on, until the battery capacity is completely consumed. In this way, we can guarantee the battery packa long life under the high load capacity.

3. Product application areas

- Smart meters (clock battery)

- Water meter

- Gas meter

- Heat meter

- The OBU unit in intelligent transportation ETC

- High voltage fault indicator

- Patrolling unit

- TPMS automobile tire pressure monitoring

4. FAQS of General Safety Instructions

- What the danger is if the battery is closed to the fire?

They are going to be hot in very short time and it will lead the leakage of gas and toxic materials which may cause a big rupture.

- If the positive and negative polarity of a battery is directly connected, what will happen?

The batteries can’t be short circuit. If positive and negative polarity of a battery is directly connected, this may cause a short circuit and this may lead to toxic materials or gas leakage and/or violent rupture.

- When the batteries are changed, what should you pay attention to?

The batteries of different electrochemical system, grades, or brands can’t be mixed because it would lead toxic material or gas leakage and/or a big rupture.

- What should be followed during the batteries disposal?

Battery disposal method should be in accordance with local and state regulations.

HCB Battery Co., Ltd

HCB Battery Co., Ltd. was founded in 2001. As a leading primary lithium battery manufacturer and solution provider in China, HCB remains dedicated to leading the R&D and manufacturing of various types of primary lithium batteries.

With every improvement that is made, HCB continues to pursue perfection. Technological development & innovation are of great importance to HCB. We have been focusing on providing reliable products & services to the customers worldwides for more than 23 years.

Utility Metering

Automatic meter reading(AMR), advanced metering

infrastructure(AMI),electricity meters, gas meters, water meters,

heat meters, etc.

Security

Smoke detectors,0. security alarms, seismometers, digital door lock

system, etc.

Internet of Things

Asset tracking toll-gate transponders smart home bike-sharing IC

cards GPS, TPMS, RFID, etc.

Monitoring

Animal health monitoring system,forest fire alert, smart irrigation

system, etc.

Medical Devices

Cardiac pacemaker, respirator, oxygenator, inspection devices,

monitoring devices, infusion pump, etc.

Marine & Lifesaving

Life jacket, signal light, buoy, etc.

Oil & Gas

Well pressure meters, float meters, logging while drilling(LWD),

measure while drilling(MWD), etc.

Military & Defence

Portable radio communications, night vision equipment & thermal

images, torches & lamps, etc.

Our products have exported worldwide and won the trust of all, we are striving for the credibility and honor of MADE IN CHINA products.

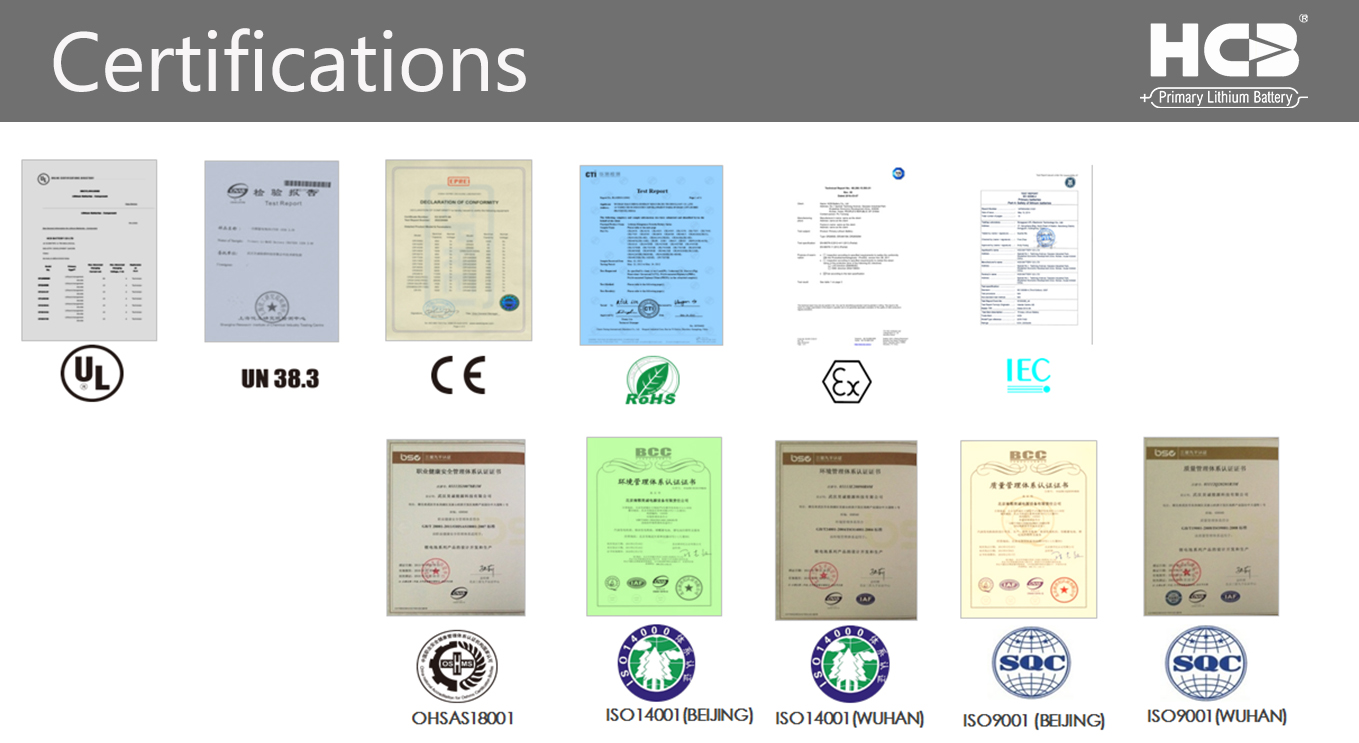

As a company seeking perfection continuously, we have strict requirements for management. The company has been awarded with OHSMS18000, ISO9001 international quality management system certificate and ISO14000 environmental management system certification. At the same time, as a company present in the extensive international market, HaoCheng has also received the CE product safety certification in EU to ensure the safety of our products exported to EU. Besides, HaoCheng has also been awarded with RoHS environmental certification in EU. Our products have passed the test for hazardous substances, thus proving the environmental features of the products. Meanwhile, because the international market has very critical requirements for shipping, we have been awarded with the UN safe shipping certification of US. Besides, our products have also received the UL American products access certification, which is necessary for all products to enter markets in developed nations such as US.

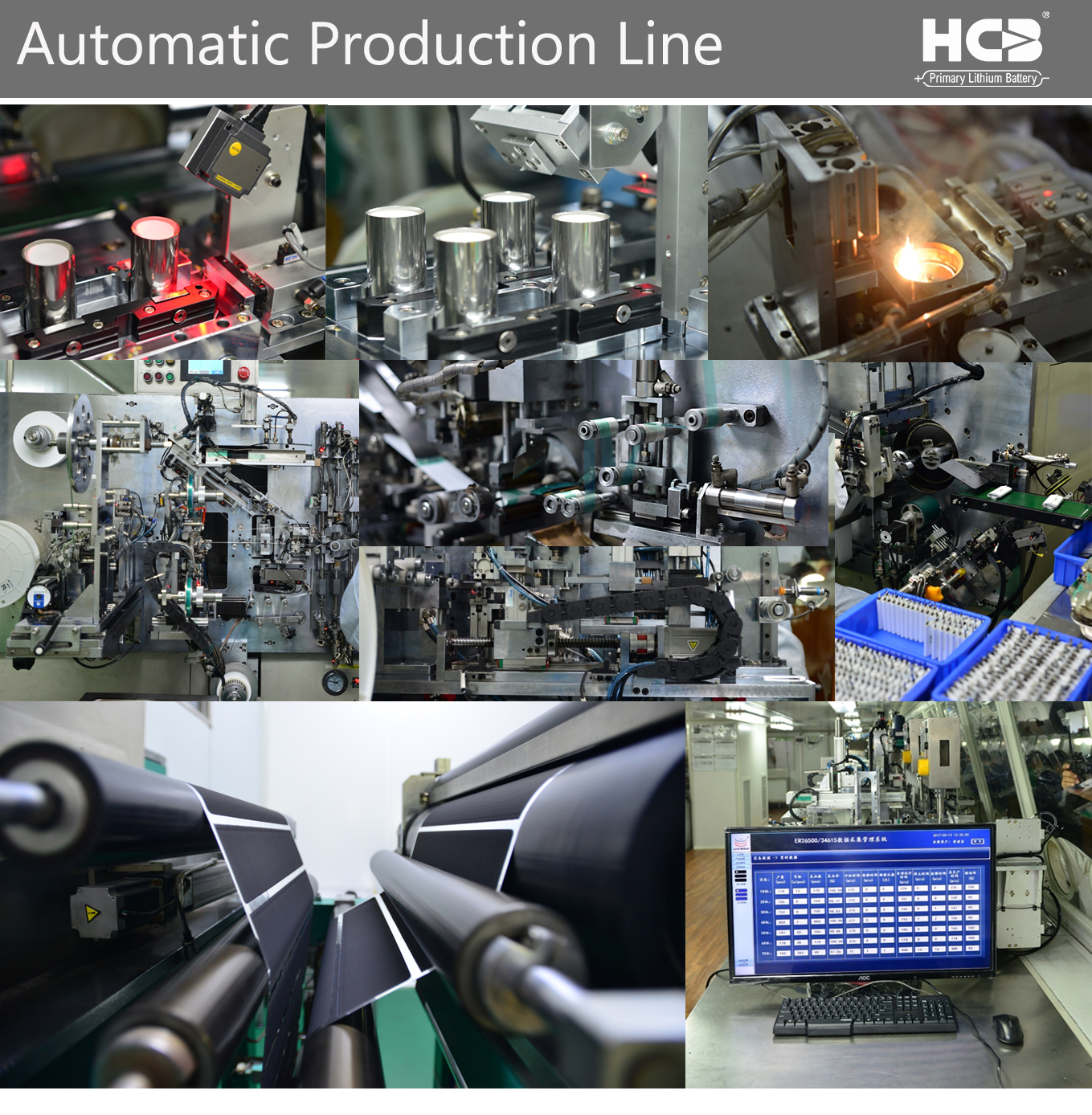

We have the automatic equipment taking the leading position in

China, the fully-automatic lithium manganese coilers (the most in

China), lithium automatic production line and laser welder imported

from Germany (we used to be the sole Chinese producer having the

equipment. Only in recent years, our Chinese competitors began to

import such equipment). The price of this laser welder is

equivalent to that of a whole

lithium automatic production line. We have invested heavily to buy

it because the laser welder only spends 0.7 seconds to weld one

battery. It is well known that the ordinary argon arc welder takes

a longer time (about 4 seconds). At the same time, the high

temperature in the welding would impact on the internal structure

in the battery. However, the laser welding greatly reduces the time

of heat conducting, thus reducing the

impact on the battery quality in the process of welding. At the

same time, the highly-automatic production equipment considerably

improves the consistency of batteries, thus ensuring the batch

supply of products.

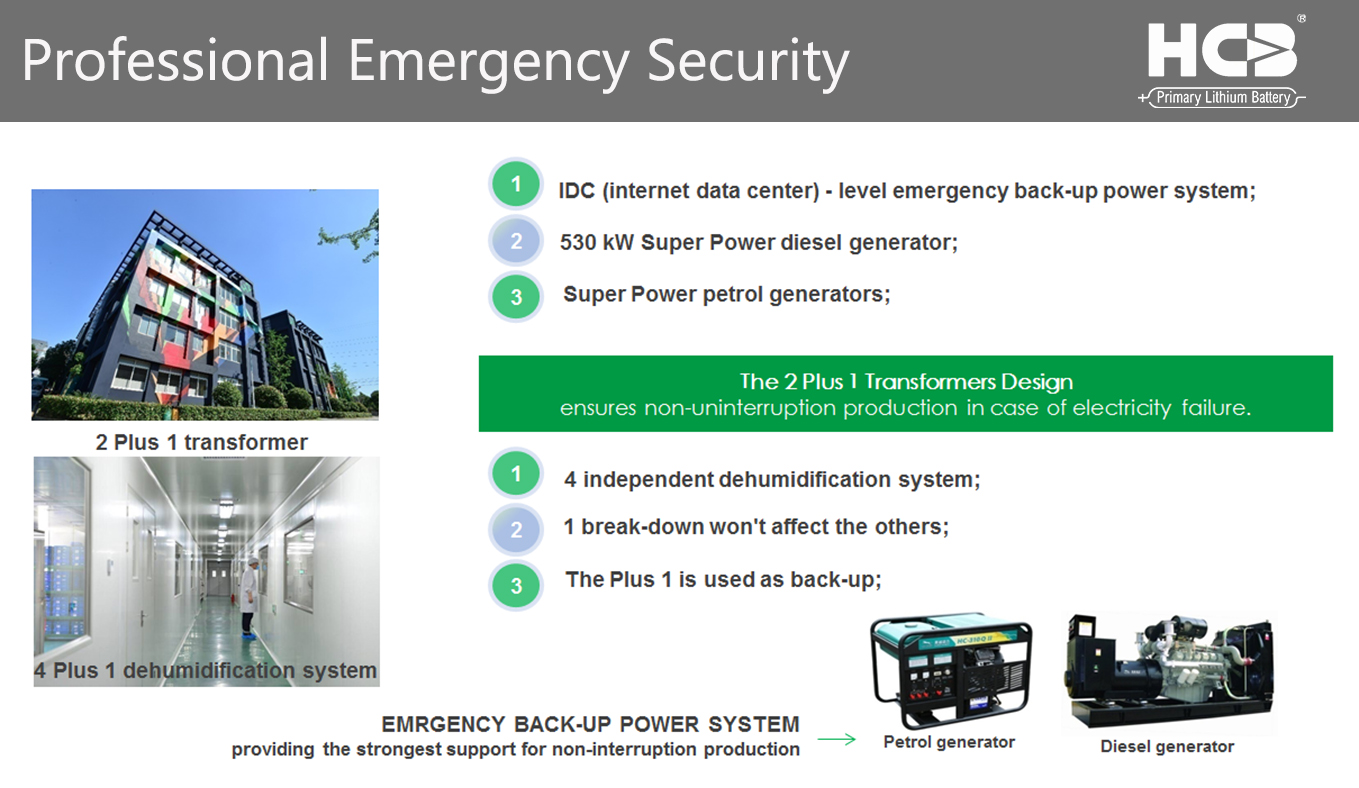

HaoCheng Industrial Park has the professional solutions to stand-by emergency power source. By taking our own advantages, we can guarantee the constant supply of power in critical moments. We have designed IDC-level (data center) emergency stand-by power source solutions for the factory, which is equipped with the self-produced Super Power 530kw diesel power generating unit. In the early stage of factory design, we use the 1+1 double transformer configuration to ensure the constant power supply for production at high cost. As is known to all, dry environment is very important in the process of manufacturing lithium batteries. The moisture will impact on the quality of batteries.

HaoCheng Industrial Park is equipped with 3+1 independent drying and moisture-eliminating system and lithium manganese, lithium thionyl and soft package sets. When one machine breaks down, the battery production will not stop. The drying and moisture-eliminating system of the original HaoCheng company has now become the spare part in the Industrial Park to ensure the lithium battery production is always done

in the wonderful dry environment.

With Experience of 24Years

And Wisdom of 600 Persons

We Do only One Thing